Just recently in KZN, the DTI came face to face with 300 small businesses seeking opportunities in agro-processing. Faced with an increasing unemployment, it was the view of government and development finance institutions (DFI) that agro-processing could boost job creation in the country.

However, DFI’s themselves have been accused of placing strict barriers for small food processing companies to access grant support.

“It is a plethora of requirements that are simply unattainable or achievable. When we apply, it even takes months to get feedback all the while we missing out on market opportunities” said one of the attendee addressing the Deputy Minister of Trade and Industry Nomalungelo Gina during question and answer session.

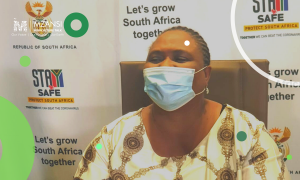

The deputy minister acknowledged the slow process and heeded the call to conduct roadshows with DFI’s. “The development finance agencies have been created specifically to assist you make success of your businesses. Government is committed to ensuring that you do not only get funding for your business from these agencies, but also that you are provided with assistance when it comes to accessing the market” she said.

But this acknowledgement comes at a time when agro-processing industry was importing more products sitting at a trade deficit of approximately R35.80 billion.

In 2018, the Dutch Embassy in South Africa together with local agencies produced a study on agro-processing whose findings projected a troubling feat. Growth of the agro-processing industry was stymied by finding qualified personnel with the right skillset and experience to train processors, lack of access to finance and inputs, and the high capital investment agro-processing required.

There were close to 1800 food production companies in South Africa with the top ten responsible for 70% of the agro-processing turnover. A small number of players in the hot sauce market were finding it tough to compete due to the unavailability of machinery and its associated cost.

“Machinery is expensive and government is there to provide funding but it is not augmented by training and providing inputs. I have to figure out the machine by myself and in the process, I incur heavy costs of production -you end up giving up” advised one entrepreneur in attendance.

Frankly, the South African government seemed to have underestimated the weight and intensive demand the agro-processing industry on its shoulders. Still today, the country is incapable of producing its own agro-processing technologies and professionals to train emerging processors explaining the delayed take-off.

Netherlands produces twice as much food using half as many resources. It has strengthened its food processing industry climbing the ladder in second place as a food exporting country in the world. In the two decades, the Netherlands has built machinery such as soft fruit pickers automated meat separators and potato processing creating an avalanche of jobs opportunities.

The policy asunder between the dti and department of agriculture, land reform and rural development (DALRRD) on agro-processing was argued to be the leading cause of emerging processors losing hope in frustration.

Dti focussed largely in ensuring agro-processors access international markets yet local small players were not capacitated or incentivised enough by DALRRD and DFI’s to compete locally. The joint Agri-processors Forum established by dti and DALRRD in 2014 was meant to unbundle policy confusion on agro-processing but nothing so far has come out of it.

“Sessions like these are meant to point you to the right places where you can get the relevant information in order to empower yourself and grow your company. We would like to see more companies from KwaZulu-Natal in general, and Newcastle in particular participating in those trade missions and exhibitions,” said Gina